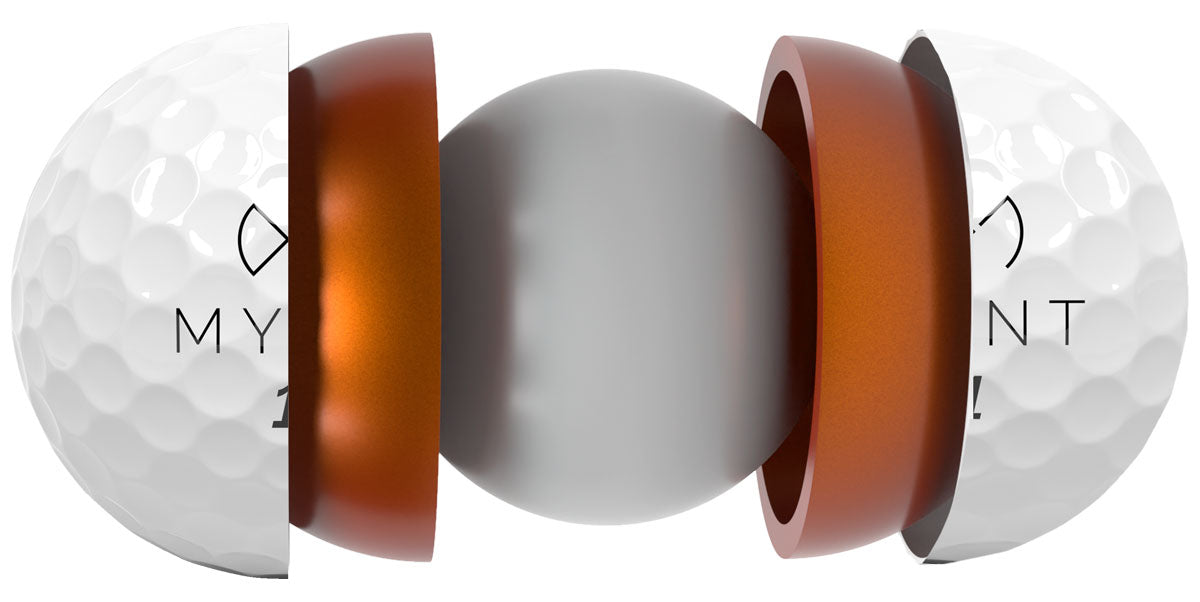

A golf ball is constructed using several layers of materials that are specifically designed to optimize its flight characteristics and control. The construction and materials used can vary between different types of golf balls, but here is a general overview of how a typical golf ball is constructed:

- Core: The core of a golf ball is typically made from rubber or synthetic material, and is designed to provide the ball with its basic properties, such as hardness and compression. The size and hardness of the core can influence the distance and control of the ball.

- Mantle layer: The mantle layer surrounds the core and is typically made from a combination of materials, such as rubber and synthetic polymers. The mantle layer can affect the ball's spin and speed and is often designed to optimize distance and control.

- Cover layer: The cover layer is the outermost layer of the golf ball and is designed to provide durability and aerodynamic performance. The cover can be made from a variety of materials, such as plastic, urethane, or a combination of materials.

- Dimples: Dimples are small depressions on the surface of the ball that are designed to reduce air resistance and increase lift, helping the ball to travel further and more accurately.

The materials used in golf balls can vary depending on the specific characteristics that are being targeted. For example, the core of a distance ball may be made from a harder material to maximize distance, while a control ball may use a softer core for increased spin and feel. The cover layer may also be made from different materials to provide different levels of durability and spin control.

Overall, the construction and materials used in a golf ball are carefully designed to optimize performance for different types of golfers and different situations on the course.